Offer

- stock-no.:

- 0200720

- type of machine:

- Table Type Boring and Milling Machine

- make:

- UNION CHEMNITZ

- model:

- KCUX 130 CNC 840 D

- year of manufacture:

- 2002/ Überholt 2020

- type of control:

- CNC

- country of origin:

- Germany

- freight basis:

- EXW, free on truck unpacked

- storage location:

- Leipzig 5

- delivery time:

- immediately

- price:

- on request

technical details

- boring spindle diameter:

- 130 mm

- x-axis:

- 3200 mm

- y-axis:

- 2500 mm

- z-axis:

- 1500 mm

- b-axis:

- 360 °

- w-axis:

- 750 mm

- U-axis:

- 220 mm

- control:

- Siemens 840 D

- tool taper:

- HSK 100

- revolution per minute:

- 2,5-280 Plansupport U/min

- range of rpm - spindle:

- 5-3000 U/min

- clamping table:

- 1600x2000 mm

- feed speeds:

- Z/Y/W , 1....6.000 mm/min

- rapid traverse :

- Z/Y/W , 15 m/min

- max. torque on the spindle:

- 2415 Nm

- weight of tools max.:

- 25 kg

- tool changer with:

- 60 Plätzen/place

- diameter of tools max.:

- 250 mm

- tool length max.:

- 500 mm

- table load:

- 6,5 t

- coolant device:

- IKZ / CTS

- total power requirement:

- 51 kW

- weight of the machine ca.:

- 32 t

- dimension machine approx.LxWxH:

- 8,5x8,2x4,5m m

- dimensions electric cabinet LxWxH:

- 2,0x0,68x2,3 m

- coolant tank:

- 1245 l

additional information

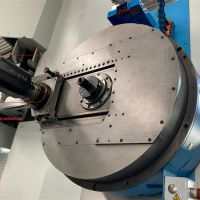

7-AXIS Machining CENTRE HORIZONTAL / Domestic Warranty 6 months!

The table boring machine has been mechanically overhauled.

Further details:

- Tool holding intake boring spindle taper hollow shank HSK-A 100

- Tool holder face support taper hollow shank HSK-C 100

- CTS and external cooling

- Work table with pallet changing system (automatic workpiece change) Standard pallet change with 2 stations in z-axis direction.

- Exchange of workpieces (max. 6.5to) in the machining work cycle.

- Loading and unloading station for 2 pallets size each 1600x2000mm

- controlled cross slide Ø=700mm (interpolation with other axes possible)

- Cooling device/ belt filter system brand Bürener

- Slat-band chain conveyor

- Display Monitor control panel 15 Inch

- Funk Meßtaster 20.00 Multi Radio Waveprobe

- Werkzeugmeßgerät Laser Blum

The T-slot clamping plate shown in the photo is not included in the offer!

work carried out:

- Overhaul of the complete headstock

- W-axis optimized for better lifetime / wear resistance (sleeve with ceramic coating)

- Renewal of the linear guides of x-, w-, z- and y-axis

- Headstock overhauled by manufacturer.

- Assembly, reconditioning and reassembly of the facing slide

- Renewal of all hydraulic hoses according to DIN 20 066

- Renewal of the lubrication pipes

- Renewal of the central lubrication unit of the X-axis

- Dismantling of the clamping shoes of the X and Y axis, cleaning, renewing of linings

- Seals of hydraulic components renewed

- guideway covers refurbished and wiper lips renewed

- Chip conveyor cleaned, checked, defective bearings replaced

- Pallets cleaned, checked, defective rollers replaced

- Cleaning, inspection, painting of the coolant system

- Tool changer checked, and partly overhauled by the manufacturer

- Complete repainting of the machine

Sorry the machine has been sold already! Here you will find more machines referring to your required category.