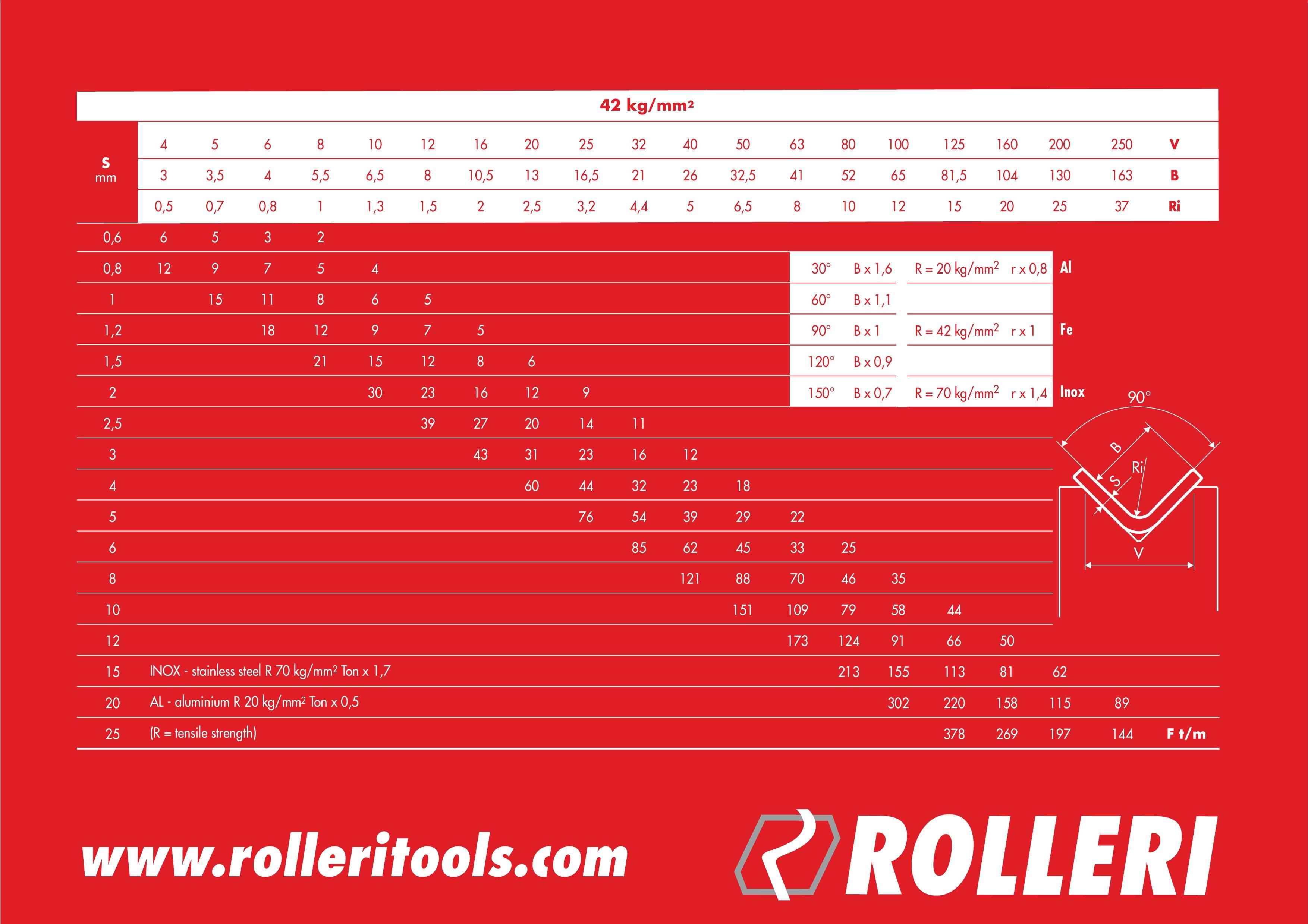

Calculating Bending Force for Pressbrakes

The calculation of bending force in which KN is necessary to fold a certain thickness results from several factors. The following factors are important:

- The material thickness which strength you want to fold.

- The bending strength of the steel, which would like to fold.

- For instance: Steel S235 / 450 N / mm ² bending strength / steel S355 / 620 N / mm ² / RVS (stainless steel) / 700 N / mm ², Alu / 280 N / mm ²

- V-opening should always be to calculated the 8 times of the material you want to fold. For example at a plate thickness of 5mm x 8 = V = 40mm. The length of the material, which you would like to fold. With the chart below, this can be done quickly based on mild steel S235:

Source of the diagram:

www.rolleritools.com

An example for the use of the chart above:

You want for eg. to fold a steel sheet type of steel S235 / 3000mm length with a thickness of 3mm. This example is based on an angle of 90 °. The sheet thickness of the to fold material should be calculated 8 times from the thickness of the material is leading to the V (see diagram drawing) . At a thickness of 3mm multiplied 8-times would be the result = V = 24mm. Thus, the coordinates in Table S (thickness) at 3 mm and at 25 V to give crosses determines the coordinates and the result 23t / m and multiplied by the bending length in our example 3m. Is leading to a final result of 69 ton bending force. The result is showing that you require at least a minimum pressure of 69t to fold sheets on a total length of 3 meter. This chart should be seen as slight help, but not to forget there are also a few other components such as hardness and type of the tool which will be used to give a clear statement and fixed statement regarding the required bending force.

The content and technical details has been researched by us. We are giving no warranty of correctness.