Offer

- stock-no.:

- 0100036

- type of machine:

- CNC - production lines for window

- make:

- Ingenierbüro Maschinenbau GmbH BJM

- model:

- RF-9L / H

- year of manufacture:

- 1998

- type of control:

- CNC

- country of origin:

- Germany

- freight basis:

- ex location Bitterfeld, free on truck

- storage location:

- Wolfen-Bitterfeld

- delivery time:

- immediately

- price:

- on request

technical details

- tube diameter max.:

- mm

- tube diameter min.:

- mm

- wall thickness max.:

- mm

- profile width:

- 50 mm

- Air volume:

- m³/h

- work height max.:

- 950 mm

- interface:

- RS 232 Pinout

- band speed:

- m/min

- total power requirement:

- kVA

- Weight approx.:

- t

- dimensions of machine:

- mm

- dimension working table:

additional information

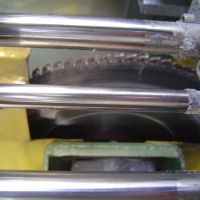

Window profile processing machine

for materials such as plastic, aluminum and wooden windows in a continuous process. The materials are conveyed by a pneumatic transport and clamping system.

The system consists of two work stations (machines), an electrical control cabinet, and a control panel and transport units.

As well as columns with transport system vibrator, chip transport unit and column with receipt printer.

Our photos are first taken from the location and then further pictures are how the plant is stored in our stock ready for transport.

Workstation no. 1 (machine 1):

-sawing station with saw blade Ø 400 x 4,5mm

-drilling unit with clamping cartridge (vertical upwards)

-drilling unit with clamping cartridge (hotizontal)

-Boring with clamping cartridge (vertical down)

-twin drilling unit with clamping cartridge (vertical down)

-45° drilling unit with clamping cartridge (upwards)

Working station no. 2 (machine 2):

-drilling unit with clamping cartridge (vertical upwards)

-milling spindle horizontal with 11 side milling cutters

-Drilling unit with clamping cartridge (vertical down)

-Drilling unit with clamping cartridge (vertical upwards)

-Drilling unit with clamping cartridge horizontal

2 transport units: motor driven

-LxWxH: 5.650 x 2.400 x 1.000mm

-track width 1.980mm

2 pieces transport units: motor driven

-LxWxH: 2.150 x 2.750 x 1.050mm

-track width 2.300mm