Offer

- stock-no.:

- 0100804

- type of machine:

- Wire Straightening and Cutting Machine

- make:

- Macsoft

- model:

- F 412

- year of manufacture:

- 1995

- type of control:

- CNC

- country of origin:

- France

- freight basis:

- EXW, free on truck unpacked

- storage location:

- Leipzig 5

- delivery time:

- immediately

- price:

- on request

technical details

- wire diameter - max.:

- mm

- wire diameter - min.:

- mm

- wire length:

- mm

- wire diameter - min.:

- 4 mm

- wire diameter - max.:

- 12 mm

- wire length:

- variable mm

- control:

- Macsoft

- Total power requirement:

- ca. 10 kW

- Weight approx.:

- 4,0 t

- dimension machine approx.LxWxH:

- 1,9 x 4,2 x 2,0 m

- transport measurements machine:

- 4,2 x 2,0 x 2,0 m

- transport dimensions LxWxH:

- Haspel: 2,2 x 1,5 x 1,5 m

- transport dimensions LxWxH:

- Bedienpult: 0,7 x 0,8 x 2,0 m

additional information

WIRE STRAIGHTENING AND CUTTING MACHINE with coil

The machine is currently pre-equipped for a Ø 8mm wire.

The machine is electrically pre-equipped for a protective grid.

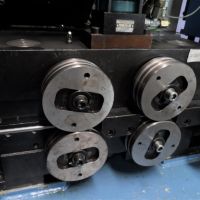

Number of feed rollers GR1+GR2 = 2x2 pair, Ø 120 x 40mm hydraulic

manual hour counter for control on: (currently 11.348 hours)

Straightening unit:

Straightening rollers Ø 72 x 25mm 7 pieces horizontal and 7 pieces vertical, travelling, in continuous process

Measuring roller run, manual clamping

Cutting unit:

automatic / manual, hydraulic

Material up-take via reel:

Size 2100 x 1500 x 1500mm

wire ring up-take: outside Ø 1000mm, inside Ø 550mm, height 650mm

accessories:

-div. bending and straightening tools for Ø 8, Ø 10 and Ø 12mm (as in photo) available.

-Feeding rollers, clamping and auxiliary tools and spare parts ( some on the machine)

-Straightening unit for straightening rolls Ø 40 x 25mm with 11 pieces horizontal and 7 pieces vertical, running along

i.D.

Sorry the machine has been sold already! Here you will find more machines referring to your required category.